This is the fifth in a series of articles that highlight contributions of Milwaukee-area industry to the war effort during World War II. Many thousands of Milwaukeeans, men and women, helped to provide the munitions and other products to make Victory possible.

Earlier articles in this series chronicled the activities during the Second World War of Milwaukee companies Allis-Chalmers, A.O. Smith, Briggs & Stratton, Globe Union, Milwaukee Ordnance, JW Speaker, David White, and South Milwaukee’s Bucyrus-Erie. These companies were far from alone in contributing to the war effort. This edition covers a few more of the dozens of Milwaukee-area companies that provided the United States and its allies with the munitions, equipment, and supplies for the war effort. Collectively, along with other manufacturing companies across the United States, they were called America’s ‘Arsenal of Democracy.’ Collectively, they helped achieve Victory in Europe and Victory Over Japan.

This article discusses the important contributions of some of the companies that manufactured the engines to power the machinery used during the war.

The Milwaukee area has been a persistent center of United States excellence in the manufacture of internal combustion engines. More IC engines have likely been produced in the area than in any other US manufacturing center. Milwaukee-built engines have been used to power numerous machines that were important to the economy—they were also important to the war effort.

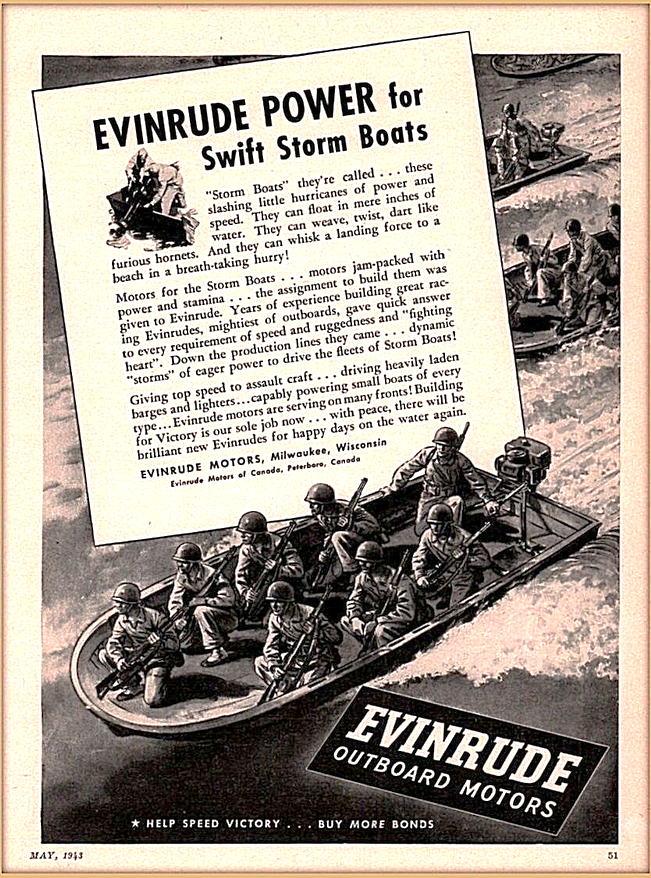

Ole Evinrude developed the first commercially successful outboard motor in 1909. Upon his death in 1933, his son Ralph took over the day-to-day management of the company. During the Second World War, Evinrude was called upon to provide power for what became known as the Storm Boats. They also provided outboard motors for inflatable rafts, which were sometimes dropped to downed pilots and bomber crews.

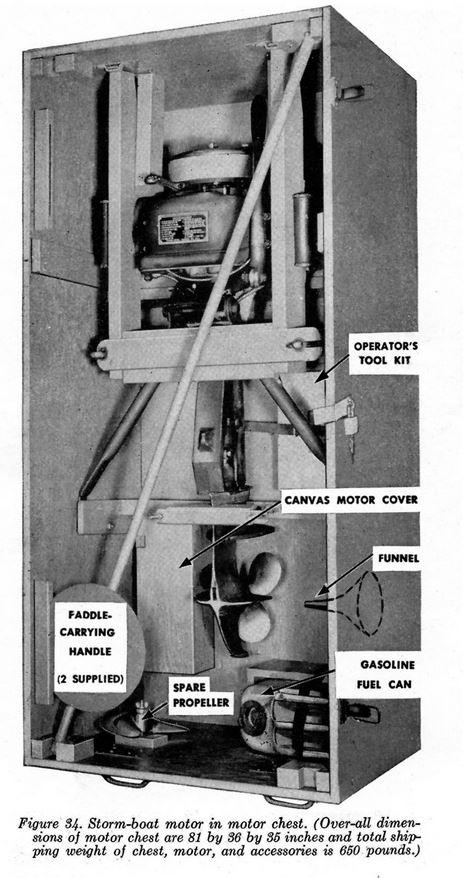

The Storm Boats were assault boats, designed in England but built in the United States. They were designed to cross major rivers since the German army detonated the bridges as they retreated. A powerful engine was needed to propel the boats, especially for crossing the Rhine which had an 8-knot current. Evinrude modified their four-cylinder engine, model 4-60, for the service. The engine provided 50-hp, which was a huge step-up from the 5- to 10-hp engines typically used for recreation at the time.

Combat engineers were used to operating the storm boats, with nine soldiers typically laying as low as possible along the bottom. The boats were reportedly driven into the beach at 25 mph, at which time the soldiers would roll out and deploy. The combat engineers would then head back to bring another group. Over 300,000 soldiers were taken across the Rhine River in this fashion in a single day.

When interviewed about the importance of the river crossings by Storm Boats, General Eisenhower replied that he thought there would have been a lot of trouble winning the war without outboards.

Outboard motors were also used extensively in the Pacific war theaters to attack Japanese forces. It is reported that inflatable rafts with outboard motors were also dropped to downed pilots and bomber crews, saving over seven hundred lives.

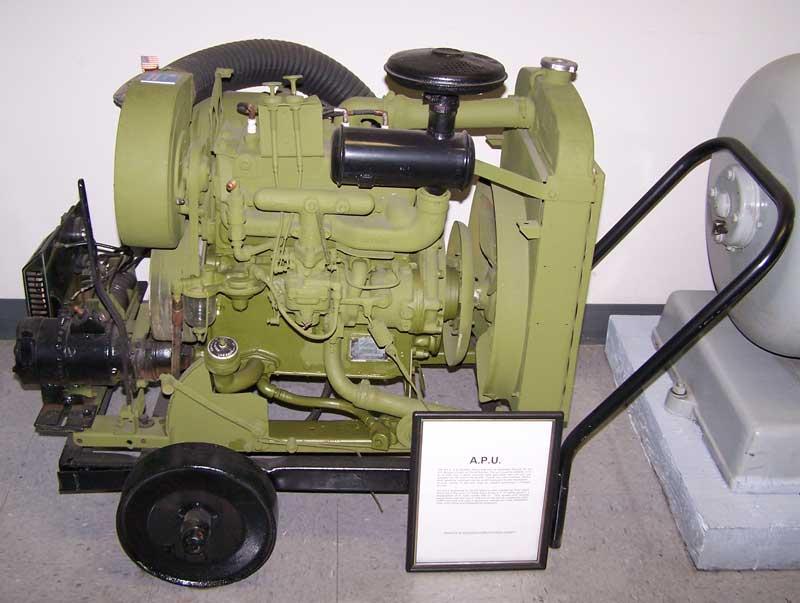

We are all familiar with Briggs & Stratton’s engines for lawnmowers and other such uses. The company is the world’s largest manufacturer of small internal-combustion engines. During WWII, the company was called upon to produce engines for various military uses that ideally matched their smaller sized engines.

Briggs & Stratton introduced engines with the designations AP, I, N, U, and ZZ during 1940. The most common use was for portable electric power generation for a multitude of purposes including powering pumps for purifying water, for portable fire control, and for refueling aircraft. The small engine-generators were also used to power field lighting, cooking equipment and bread machines, aircraft engine heaters, emergency landing lights at airstrips, and air-raid sirens. The United Service Organization (USO), used them for the important task of entertaining the troops—powering loudspeakers for shows and operating movie projectors.

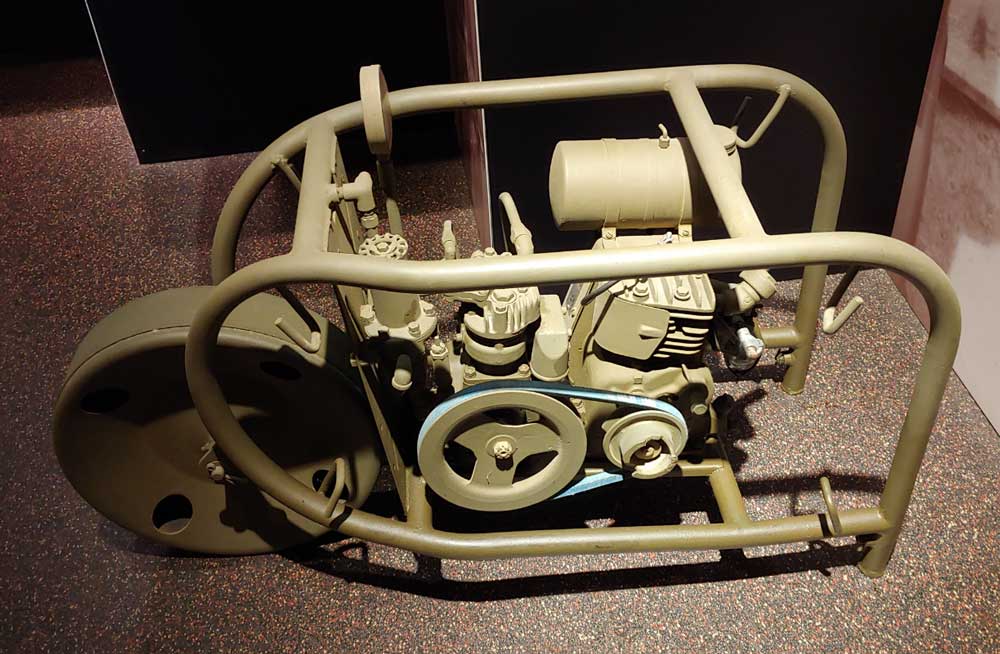

The company also introduced a portable air compressor powered by its model ‘N’ engine. The engine and compressor assembly sat within a tubular framework, which helped make it maneuverable. The frame served as a small air-receiver for the compressor. The compressor was principally used to inflate aircraft tires for the Army Air Corps and provide compressed air for various other maintenance services.

During the course of the war, Briggs & Stratton was in full production, working 24/7 to meet wartime requirements.

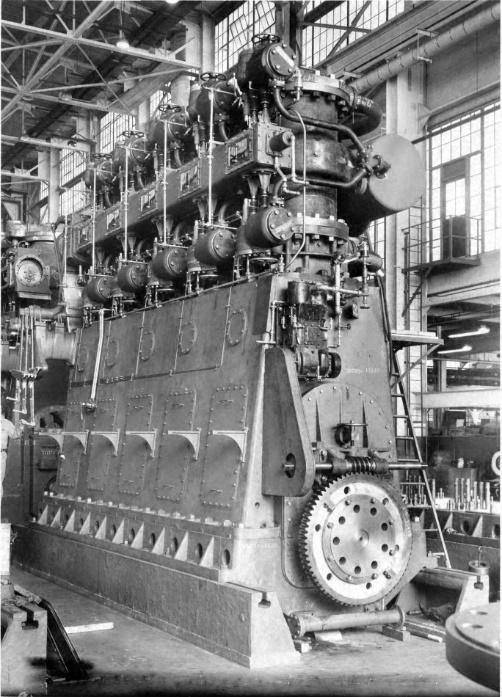

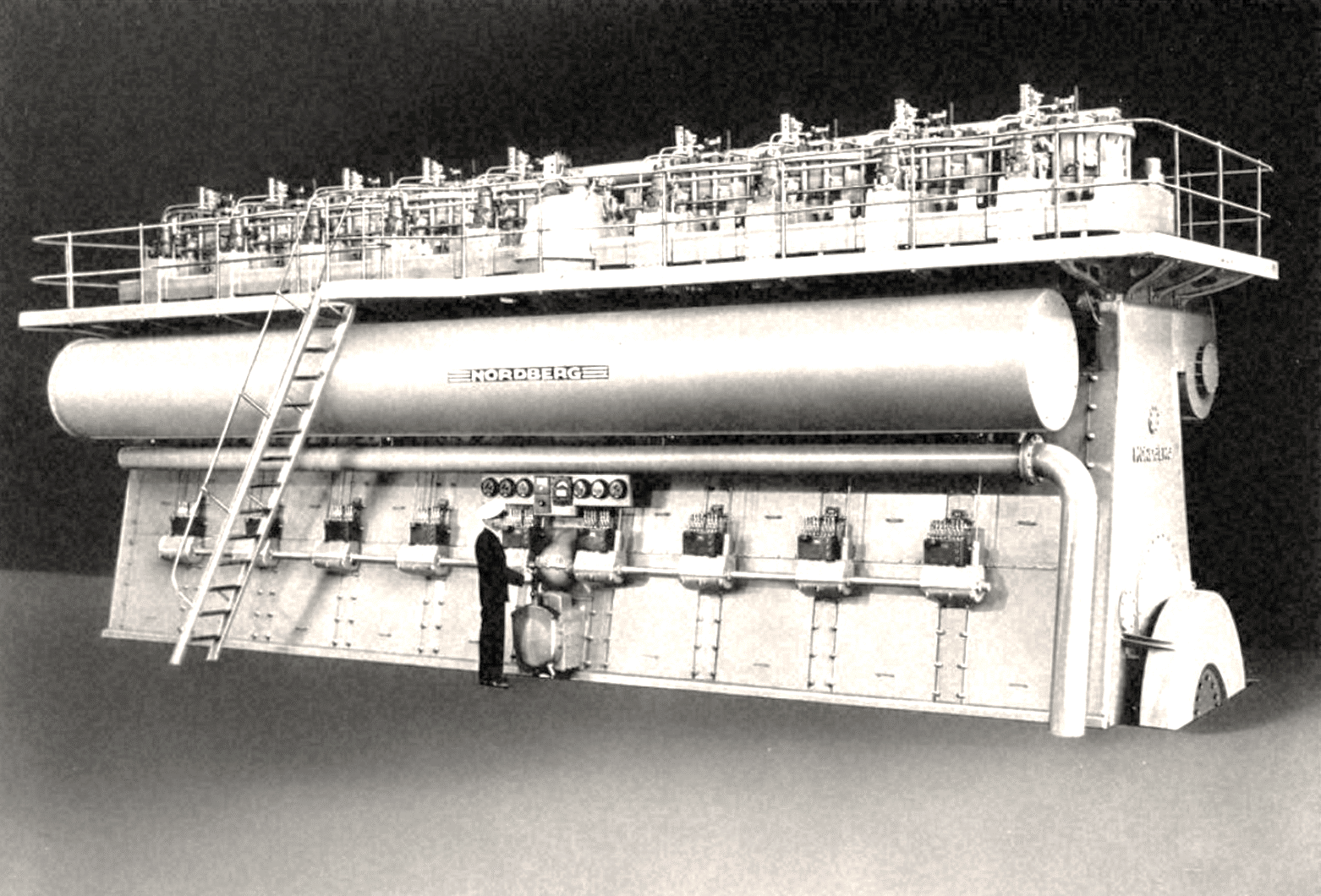

Nordberg was a leading manufacturer of marine diesel engines. During the Second World War, the company supplied engines for many of the American merchant marine ships, as well as for ‘baby flattops,’ (more formally known as escort aircraft carriers).

During the later stages of the war, Nordberg produced the largest diesel engine ever built in the United States up to that time—a six-thousand horsepower engine for the United States Maritime Commission. The nine-cylinder engine was designed for direct-drive marine service. The crankshaft alone weighed eighty-thousand pounds.

The engine used advanced “mechano-pneumatic” controls that governed starting, fuel, and speed regulation, with interlocks to prevent damage to the engine. It was powerful enough that a single engine could power a ship, compared to two normally used.

The engine was completed in 1944 and installed in the M.S. Emory Victory. The Emory was a VC-M-AP4 Victory ship with an overall length of 455 feet and a beam of 62 feet. She was launched at the Bethlehem Fairchild Yards in Baltimore, Maryland in April 1945 but wasn’t delivered until October 1945, shortly after the conclusion of the Second World War.

In addition to marine diesel engines, during the war Nordberg Corporation also produced torpedo tubes and mounts.

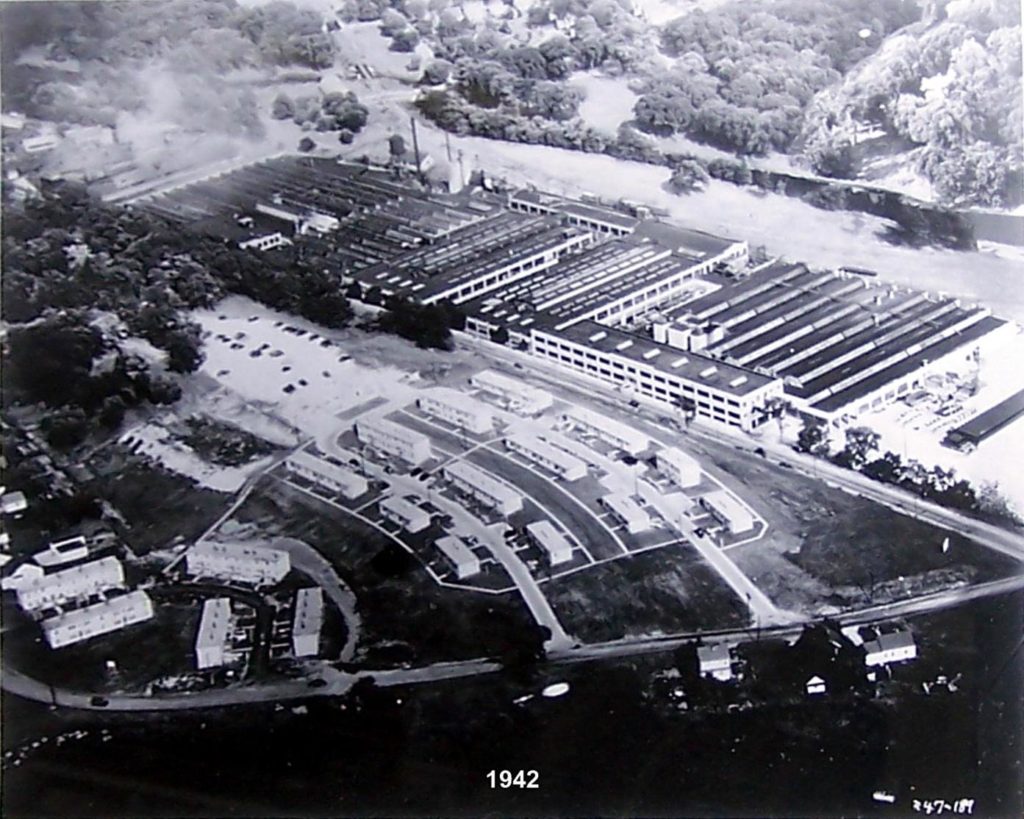

When the United States entered into the Second World War, the demand for Waukesha engines increased dramatically. The plant ran around the clock to meet the high demand for military applications. The company was asked to produce engines for trucks, tanks, and other vehicles, as well as to power pumps, blowers, generators, and similar equipment.

Waukesha Motors produced a wide range of internal combustion engines during the war, including six-cylinder engines that powered Corbit’s 2-½ ton trucks and FWD’s cab-over-engine 4X4 5-6 ton trucks. Their engines were also used on artillery tractors, military snow blowers, and other mobile military equipment.

Waukesha Motors greatly expanded its factory in order to produce the engines needed for the war effort. The workforce increased to about 2,000—many of whom were women trained to work as machinists. Barracks were built across the street from the plant to house the influx of new workers.

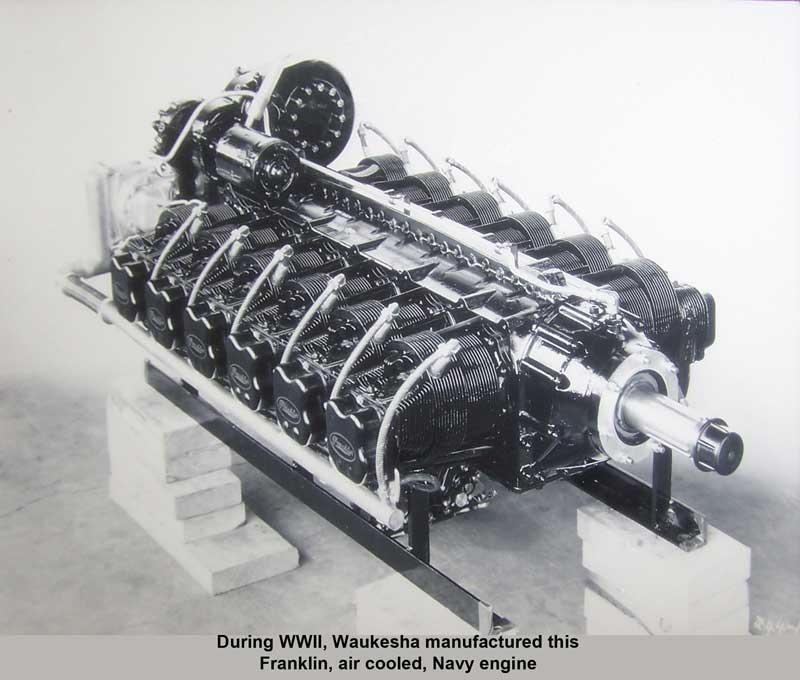

Waukesha Motor Co also produced turbines and aircraft engines.

Wisconsin Motor of West Allis’s specialty during WWII was the production of heavy-duty air-cooled internal combustion engines. They had developed air-cooled engines for various applications starting in 1929. They were so popular that by 1939 the company devoted its activities solely to air-cooled engines, producing as many as twenty-two thousand engines per month.

In 1940, Wisconsin Motor introduced what would prove to be the company’s most popular series of such engines, the Model V-series. As the name implied, the engine block was in a V-configuration. The engines had a shroud with an engine-driven fan, which forced cooling air over the finned cylinder heads.

During the war, Wisconsin Motor was asked to provide its V-Series air-cooled engines for numerous military applications, including powering mobile electric generators and construction equipment. Following the war, this led to significant demand for the company’s engines for construction equipment, and continued strong demand for agricultural applications.

By the Second World War, steam engines were pretty much a thing of the past. The steam turbine was the preferred power plant for warships use because of its greater efficiency, which extended range and increased speed. However, steam turbines required sophisticated manufacturing tooling and there were a limited number of manufacturers with the expertise to produce them. The companies that could manufacture steam turbines were already committed to producing turbines for warships.

Additional merchant ships were needed quickly in order to meet the needs of the Allies. Nazi U-boats were sinking many ships and by late 1940 Britain was experiencing severe shortages. In response, the British contracted for sixty ships from the United States. The intention was to build EC-2 cargo ships, known as Liberty Ships, faster than the Germans could sink them. United States shipyards ultimately built over 2,750.

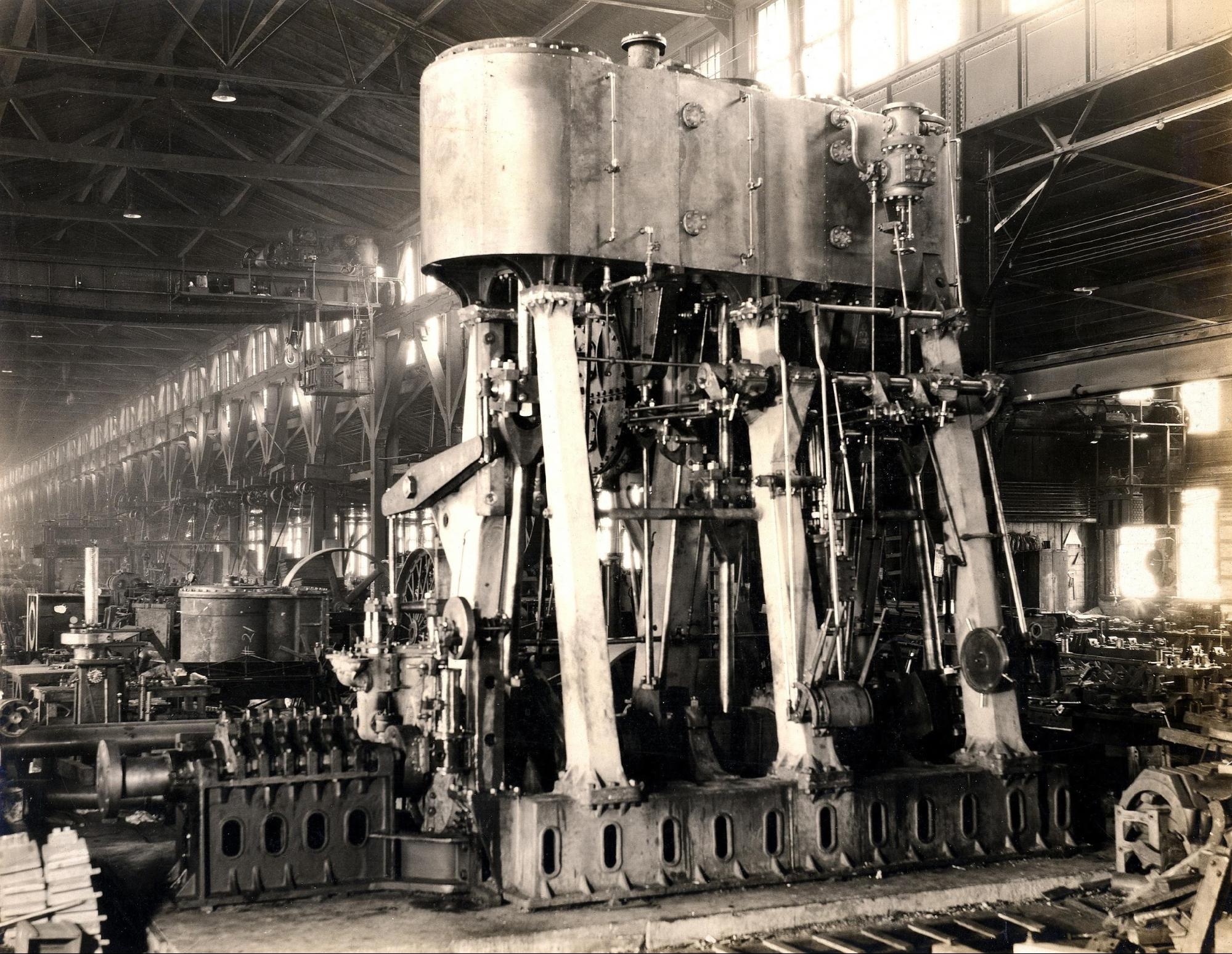

A decision was made to turn to reciprocating steam engines for the Liberty fleet. They were simpler devices and a large number of United States companies had the capability to manufacture them. A standard design was selected and shared with over a dozen different manufacturers. Parts from one manufacturer were interchangeable with parts made by another manufacturer, which facilitated quicker maintenance and repairs.

Filer & Stowell of Milwaukee was one of the companies selected to manufacture the steam engines. By May 1943, they produced over fifty of the standard 2,500 horsepower, triple-expansion marine steam engines. Each engine weighed 135 tons.

The company was awarded the “M” pennant by the Maritime Commission—the first company in the state of Wisconsin to receive this designation for outstanding production achievement.

Filer & Stowell continues in business as a producer of high-quality sawmill machinery for the lumber industry—a remarkable 150 years after being established in 1865. The company is now located at 3939 West McKinley Avenue.

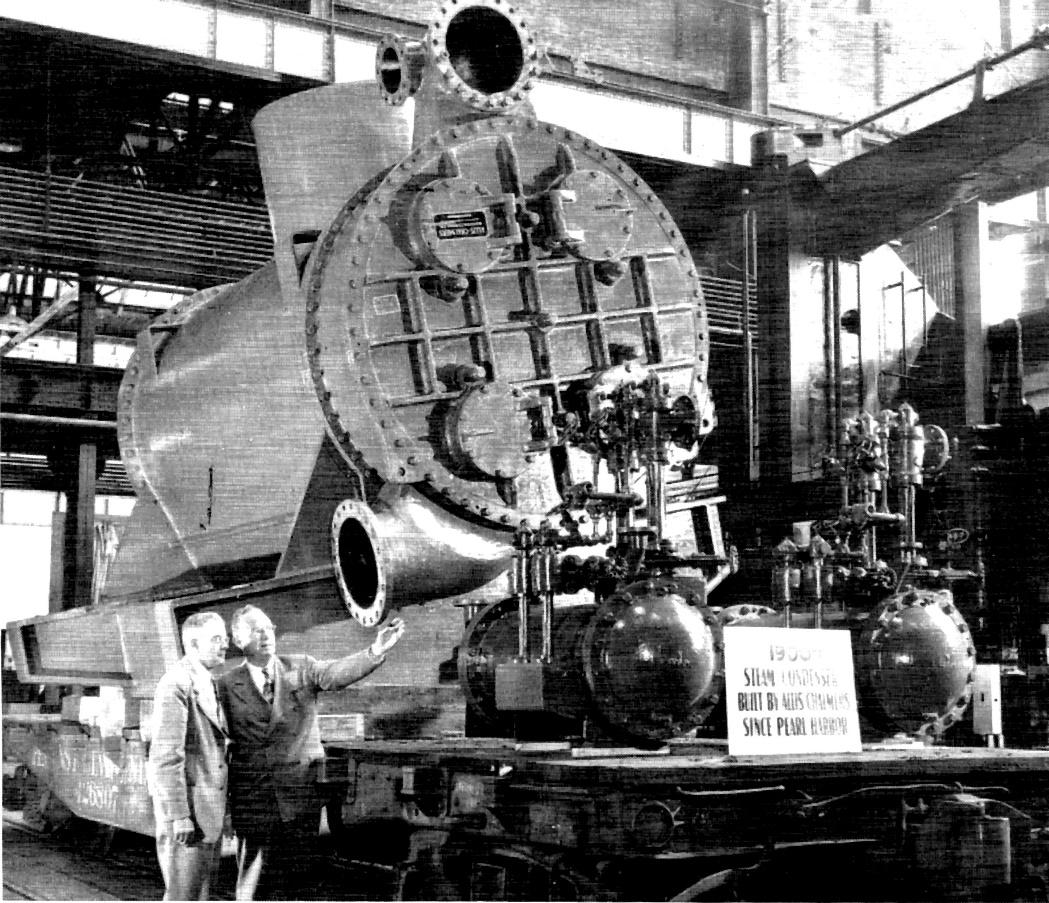

Allis-Chalmers produced steam turbines for a number of destroyers and other naval vessels, as outlined in the first article in this series. They were also a leading supplier of steam condensers for ships, producing more than one a day during the war.

Tom Fehring has written extensively about Milwaukee-area industry, highlighting innovation that resulted in the formation of numerous companies that employed hundreds of thousands of Milwaukeeans. His latest book, entitled “The Magnificent Machines of Milwaukee,” is available for sale at the Milwaukee County Historical Society, Historic Milwaukee, Boswell Books, and on Amazon.com.

Memorial Day to Labor Day

8AM-8PM daily

Labor Day to Memorial Day

8AM-6PM daily