This is the first of a series of articles that will highlight contributions of Milwaukee-area industry to the war effort during the World War II. Many thousands of Milwaukeeans, men and women, helped to provide the munitions to make Victory possible.

Prior to the Japanese attack upon the Navy base in Pearl Harbor (December 7, 1941), the United States had allowed its military arsenal to deteriorate. Counting on distance and a policy of neutrality, the country did not believe it was necessary to fund its munition industry. As one example, the United States had fewer than 1,300 combat airplanes—most of which were technologically obsolete.

However, when Germany invaded Poland, president Franklin Roosevelt called for an international trading quarantine on nations that were sparking conflict throughout the world, and began petitioning Congress to remove the ban on selling arms to those at war. The so-called ‘cash-and-carry’ program allowed sales of military implements to the ‘Allied’ nationals at war with Germany, but prohibited U.S. Ships from entering conflict zones.

The program was particularly helpful in enabling the United Kingdom to acquire much needed military equipment. It also stimulated U.S. Manufacturing interests to rebound from the Depression. When Roosevelt announced plans to produce 50,000 planes a year, Hitler scoffed, “What is America but beauty queens, millionaires, stupid records, and Hollywood?” He was to find out.

Roosevelt told the American people that he was going to ask private industry to help and intended to tap key men in American business. On May 28, 1940, he invited Bill Knudsen, Chief Executive Officer of General Motors to Washington. Almost immediately, Knudsen left his job and signed up as the first ‘dollar-a-year’ man to head up the newly formed National Defense Advisory Commission. Knudsen got to work and invited a number of other manufacturing executives to join him.

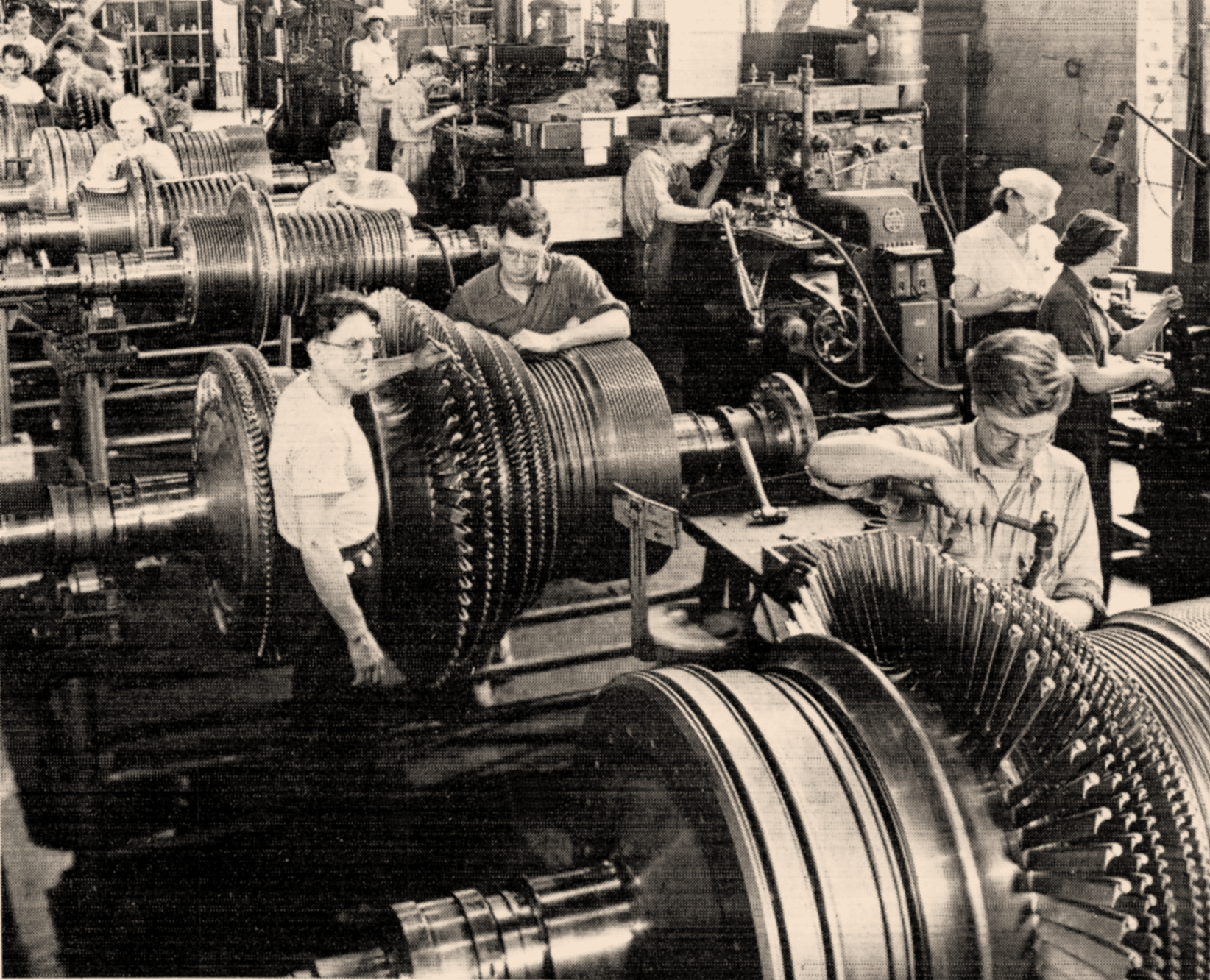

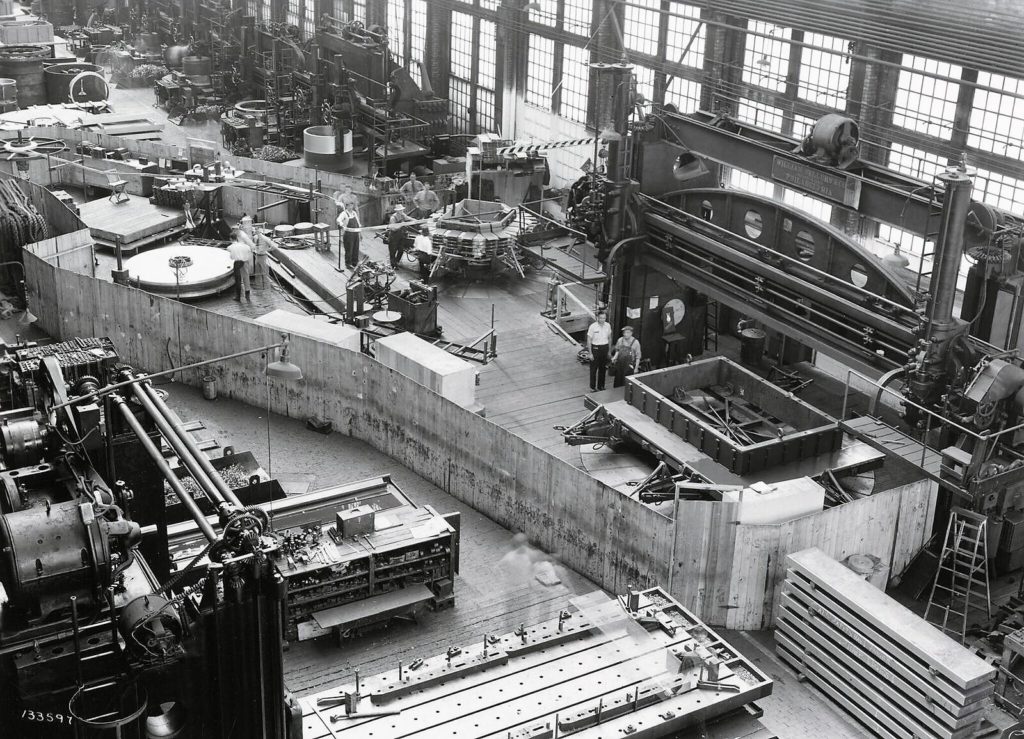

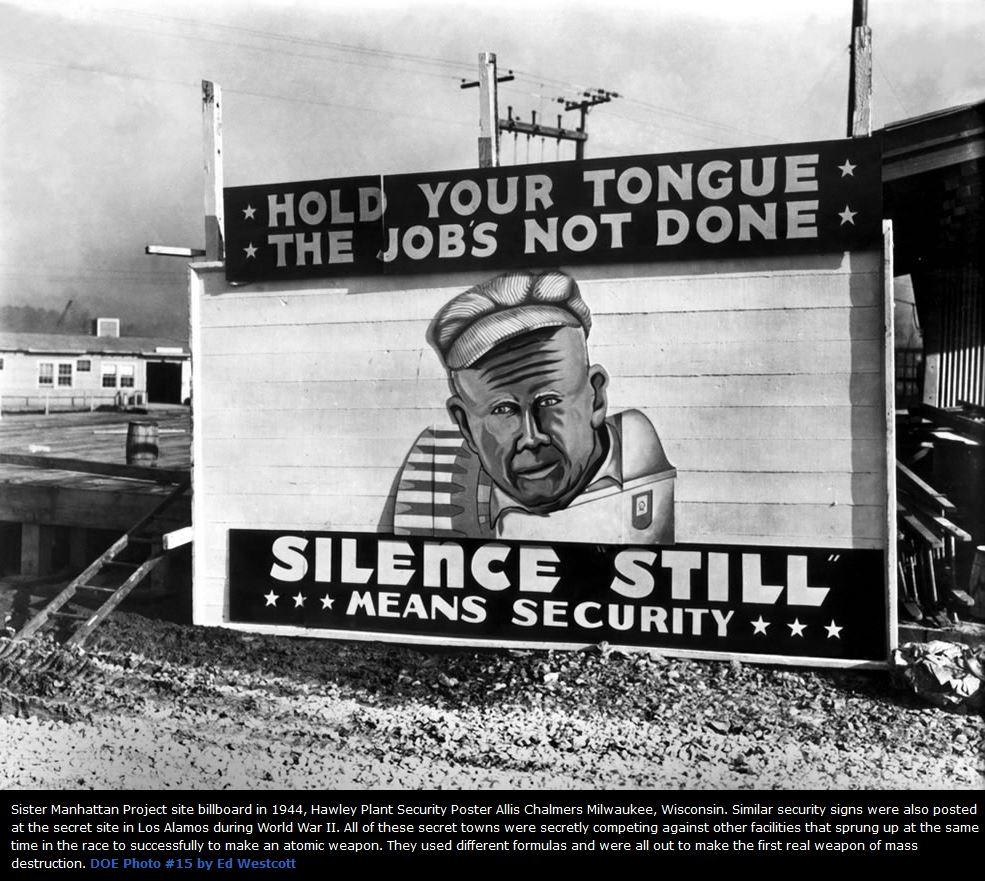

Milwaukee industry was on the forefront of this military build-up. Military orders began pouring in, as the United States and other countries sought goods from Milwaukee industries. According to Richard Pifer, in his book entitled A City at War, over $175 million in military contracts were received by Milwaukee-area industry prior to the Japanese attack. This was particularly true for Allis-Chalmers, A.O. Smith and Bucyrus-Erie. Allis-Chalmers received orders for steam-turbines for destroyers, baby flat-top escort carriers and ‘Victory Ships.’

Allis-Chalmers began work on new factories to produce turbo-supercharges for high-altitude bombers and to expand its steam-turbine production. The company produced over 100,000 superchargers during the war, totaling over 16-million horsepower. Superchargers allowed aircraft engines to operate efficiently at high altitudes (20-30,000 feet), where the air density is lower, where they were less vulnerable to enemy fire. Superchargers effectively increase the mass of air that can be drawn into the engine.

Tom Fehring has written extensively about Milwaukee-area industry, highlighting innovation that resulted in the formation of numerous companies that employed hundreds of thousands of Milwaukeeans. His latest book, entitled “The Magnificent Machines of Milwaukee,” is available for sale at the Milwaukee County Historical Society, Historic Milwaukee, Boswell Books, and on Amazon.com.

Memorial Day to Labor Day

8AM-8PM daily

Labor Day to Memorial Day

8AM-6PM daily